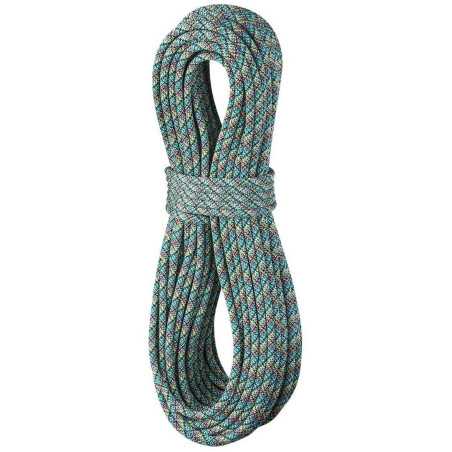

Resistant and light half rope, of extraordinary manageability thanks to the Thermo Shield treatment and with an excellent quality-price ratio. Very versatile rope for long routes, classic mountaineering and glaciers thanks to the Dry Shield treatment. Immediately ready to use thanks to the 3D Lap Coil treatment.

EDELRID - SE Roseg Dry 8,3 mm

Resistant and light half rope, of extraordinary manageability thanks to the Thermo Shield treatment and with an excellent quality-price ratio. Very versatile rope for long routes, classic mountaineering and glaciers thanks to the Dry Shield treatment. Immediately ready to use thanks to the 3D Lap Coil treatment.

A quality string at an excellent quality/price ratio.

- Dry Shield finish for better resistance to dust and humidity

- Thermo Shield treatment for greater handling

- Does not kink during use thanks to the 3D wrap

Technical features:

- 8.3mm diameter

- Number of falls: 9

- Weight: 47 g / mt

- stocking thickness: 36%

- impact force: 6.4kN

- dynamic elongation: 29%

- static elongation: 9.8%

- sock sliding: 0 mm

- Single approval: no

- Half homologation: yes

- Twin approval: no

Technologies:

- 3D Lap coils

- dryshield

- Thermo Shield

- Bluesign certification

3D Lap Coils

As soon as you have a new EDELRID rope in your hands, all you want is to start climbing right away. However, the formation of folds and twists during unrolling could quickly spoil the joy of the new purchase.

From now on, however, this eventuality, for all EDELRID strings, belongs only to the past! The new EDELRID 3D Lap Coil technology makes the unwinding operation unnecessary. In fact, we have introduced the new Lap Coiling machine into our production system, which winds our strings in a special way. Thanks also to a well-designed package, starting climbing with the new rope immediately is child's play, since it is really easy to do. The markings on the rope and the detailed description on the packaging make the operation even easier: you can therefore start using the rope immediately without annoying twisting and twisting.

Pro Dry

Untreated ropes can absorb up to 50% of their weight in water. In damp conditions these ropes become extremely heavy, unwieldy and in low temperatures they can freeze. They also lose much of their margin of safety. Pro Dry is a new treatment that has been specially developed to counteract these problems. In the first stage of the treatment, the threads that make up the core are impregnated. At the end of the braiding process, the finished rope (core and sheath) is impregnated a second time. Finally the impregnation is subjected to a thermal fixing. The result is a rope that maintains its water-repellent characteristics and resistance to dirt for a long time. The ropes dry very quickly, experience minimal weight gain in the presence of humidity and do not freeze easily when temperatures drop. Thanks to the low water absorption (1–2 % according to the UIAAWater-Repellent- Test), Pro Dry ropes maintain almost unchanged performance even in humid environments, thus offering high safety margins.

The UIAA-Water-Repellent-Test is a procedure developed by the UIAA through which it is possible to measure the water-repellence characteristics of ropes. The first stage of this test consists in subjecting a test specimen to mechanical wear over its entire surface. This test simulates the wear and tear to which the rope is actually subjected when used on rock and ice. The sample is then wetted according to a standard procedure for 15 minutes with a certain amount of water (2 l/min). The sample is weighed before and after wetting. The difference in weight between the dry and wet sample is then calculated as a percentage. The percentage of water absorbed must not exceed 5% of the weight of the sample rope. Ropes that meet this requirement can be marked with the "UIAA Water Repellent" mark.

Thermo Shield

Thermo Shield is the standard treatment to which all ropes are subjected to guarantee the unrivaled handling of EDELRID ropes. This treatment consists of a thermal process through which the threads that make up the core and the sheath of the rope are perfectly harmonized with each other. Thanks to a special heat treatment, the fibers loosen inside the rope and expand. In this way the sliding characteristics inside the rope are uniformed, making it more manageable and compact. The result is strings that don't shrink or stiffen quickly.

Bluesign certification

«Our strings are clean», out of love for the environment

Quality and safety are the basic principles that drive us from our very first steps. For the production of innovative and ecological high-performance ropes we therefore remain faithful to the creed of sustainability. It is only thanks to this principle that we are able to set new standards in sustainable rope production today.

EDELRID was the first rope manufacturer in the world capable of adapting its products to the rigorous bluesign® system, i.e. the strictest ecological standard in the world as regards the production of textile materials. It is an independent standard, internationally recognized and based on five principles: resource productivity, atmospheric emissions, occupational safety, water protection and consumer safety.

All the raw materials we use for the production of our ropes are qualified as «bluesign® approved». In harmony with the optimized production that takes place here in the Isny site, our strings obtain the «bluesign® product» label, a label which therefore represents their quality seal and guarantees that the product has a low carbon content. polluting substances, does not harm health and is manufactured with environmentally friendly processes. In this way we can fulfill the natural desire of our customers to have a product that is both safe and sustainable.

And we too have learned a lot along the way: after eight years of cooperation with Bluesign Technologies AG in Switzerland, we can draw on a wealth of experience in sustainable rope production. By adapting our entire line of ropes to the strict requirements of the bluesign® system, it was possible to achieve the following savings objectives in the phase of coloring the sock threads:

- a CO2 reduction of 62 %

- 89% water savings

- a reduction in energy consumption of 63%

- a reduction in the use of chemicals by 63%

For EDELRID this represents a further step forward towards an increasingly sustainable future: for years we have in fact been pursuing the path of sustainability and we wish to continue consistently in this direction also in the years to come. We don't do it to give ourselves a virtuous air, but to provide a logical response to the needs of changing times.

To be able to say, in good conscience, that "our strings are clean".