The Edelrid Neo 3R 9.8 mm rope marks a real milestone in the development of sustainable ropes. It is the first half rope made from reused cords. The perfect symbiosis of safety and sustainability!

Edelrid - Neo 3R 9.8 mm News 2021

A rope made of ropes!

The cycle is closing. After years of development work, we have finally managed to produce a rope made up of half of recycled ropes: the NEO 3R 9.8 MM, a milestone in sustainable rope production.

Recycling of plastics such as polyamide is generally quite simple. In fact, EDELRID has already produced products with recycled ropes.

In the case of dynamic ropes, however, things are much more difficult. The recycling process generally leads to a lower quality material. In the past, it has not been technically possible to use such material to make ropes that meet the high safety requirements of EN 892, and this is an area where no compromises can be made as, ultimately, people's lives are hanging to these ropes!

After six years of intensive research in collaboration with various institutes and state funding programs, we have finally succeeded in developing a way to produce fully EN 892 / UIAA certified ropes and made from reused pre-consumer ropes. This allows us to re-insert leftover ropes from production processes into the production cycle, thus saving resources.

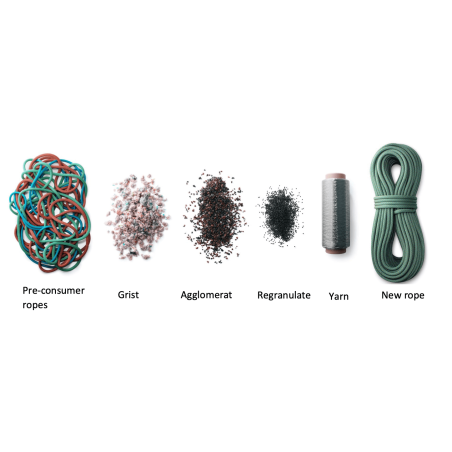

To achieve the above, the starting material is ground in a multi-step process and transformed into agglomerate and granulate. Unlike injection molding material, which is easy to produce, the challenge now lies in obtaining spinnable material that can be used to make high strength yarn. In addition, these high-performance yarns must be in harmony with other recycled and new materials, that is, they must complement each other. This is the only way to ensure compliance with the high standards of strength, elongation and other similar factors. The machines and the entire manufacturing process also need to be modified for such a rope.

On December 5th 2018, our hard work finally paid off: on this historic day, we were able to produce our first ever rope made from 100% recycled material. The fact that it will take another two years before this string can go into series production highlights the complexity of the procedure.

The world's first recycled rope will now be available at retailers from spring 2021: the NEO 3R 9.8 MM. This is made up of 50% recycled ropes.

Many people will now wonder why only 50%? Due to the low volumes and complex manufacturing process, recycled yarn is still around three times more expensive than new, conventional yarn. To offer NEO 3R 9.8 MM at an affordable price, we decided to opt for a 1: 1 ratio of recycled and new yarns.

Now it's up to consumers to make a difference. We can therefore also add the remaining 50%. We are ready when you are.

Features

- Thermo Shield treatment for easier handling

- Bluesign certification

- Does not twist during use thanks to 3D wrapping

- Processing of ropes recycled in the sock and in the core

Technical features:

- Diameter 9.8mm

- Number of falls: 5

- Impact force 8,3KN

- Weight: 63 gr / mt

- Percentage sock 38%

- elongation dinamico: 37%

- Static elongation: 7.2%

- Sock scrolling: 0

- Single approval: yes

- Half approval: no

- Twin homologation: no

- EN 892 and EU 0123 certified

- Made in Germany

Technologies:

- 3D Lap coil

- Thermo Shield

- Bluesign certification

3D Lap Coil

As soon as a new EDELRID rope is in your hands, all you want to do is start climbing right away. However, creasing and kinking during unrolling could soon spoil the joy of the new purchase.

From now on, however, this possibility, for all the EDELRID strings, belongs only to the past! The new EDELRID 3D Lap Coil technology makes the unwinding operation unnecessary. In fact, we have introduced the new Lap Coiling machine into our production system, which wraps our strings in a special way. Thanks also to a well-designed package, starting immediately to climb with the new rope is child's play, since unwinding it is really easy. The markings on the rope and the detailed description on the package make the operation even easier: you can therefore begin to use the rope immediately without annoying twists and twists.

Thermo Shield

Thermo Shield is the standard treatment to which all ropes are subjected to ensure the unrivaled handling of EDELRID ropes. This treatment consists of a termico process through which the threads that make up the core and the braid of the rope are perfectly harmonized with each other. Thanks to a special termico treatment, the fibers loosen inside the rope and expand. In this way, the sliding characteristics inside the rope are uniformed, making it more manageable and compact. The result is ropes that neither shrink nor stiffen quickly.

Bluesign certification

"Our ropes are clean," for the sake of the environment

Quality and safety are the basic principles that drive us right from our first steps. For the production of innovative and ecological high-performance ropes we therefore remain faithful to the creed of sustainability. It is only thanks to this principle that we are today able to set new standards in sustainable rope production.

Xxx_162_ was the first manufacturer of ropes in the world capable of adapting its products to the rigorous bluesign® system, which is the strictest ecological standard in the world for the production of textile materials. It is an independent standard, internationally recognized and based on five principles: resource productivity, atmospheric emissions, occupational safety, water protection and consumer safety.

All the raw materials we use for the production of our strings are qualified as «bluesign® approved». In keeping with the optimized production that takes place here at the Isny site, our strings get the 'bluesign® product' label, a label which therefore represents their quality mark and guarantees that the product has a low content of polluting substances, is not harmful to health and is manufactured with environmentally friendly processes. In this way we can fulfill the natural desire of our customers to have a product that is both safe and sustainable.

And we too have learned a lot during this journey: after eight years of collaboration with Bluesign Technologies AG in Switzerland, we can draw on a rich heritage of experience in sustainable rope production. By adapting our entire line of ropes to the rigorous requirements of the bluesign® system, it was possible to achieve the following savings objectives in the coloring of the sock yarns:

- a CO2 reduction of 62%

- water savings of 89%

- a 63% reduction in energy consumption

- a 63% reduction in the use of chemicals

For EDELRID this represents a further step towards an increasingly sustainable future: for years we have been pursuing the path of sustainability and we wish to continue consistently in this direction also in the years to come. We do this not to give ourselves a virtuous air, but to provide a logical response to the needs of the changing times.

To be able to say, in good conscience, that "our strings are clean".

You might also like

Essential office supplies in our online stationery shop that keep your office operations smooth and efficient